Most traditional applications of Lean tools have focused on manufacturing operations and paid little attention to all of the things that have to take place before an order actually gets released to the shop floor. In fact, across industries these activities account 90% of quoted lead time. Many companies have seen fantastic results floor that have resulted in little delivery improvement from the customers view.

The main reason for this situation lies in the difficulty most organizations have with measuring activity in the office, identifying wasted activity, and modifying the process in such a way that the waste is engineered out and the new process is sustainable.

We provide the following consulting resources supporting your implementation of Lean Office and Lean Service.

-

- An introductory session to clarify the role of the management and produce a macro process description for your organization.

- An internal assessment to establish baseline metrics and target priority opportunities.

- Develop a customized process improvement methodology including process improvement event contracting, execution, and follow up.

- Selection and training of internal consultant/facilitators.

Consulting

-

- Introduction and Awareness – We provide an initial working session to introduce the concepts of Lean Office/Service to your organization. In the session, you and your managers will use the basic tools of Lean Office to review your organization’s goals, develop a macro business process model, and establish key performance metrics. Senior management is usually the target audience for this activity.

- Macro Process Assessment – We will work with you to design and administer a Macro Process Assessment. It is an overall study of your business unit that examines the important aspects of customer value, the organization’s strengths and weaknesses, and opportunities for improvement.

- Macro Process Definition and performance metrics developed by the management team – A criterion-based evaluation tool is then designed to assure that the characteristics that influence your priority business concerns are evaluated.

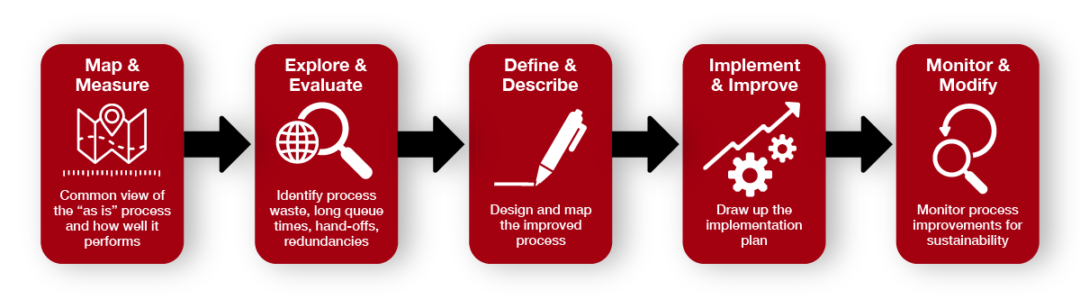

- Developing Methodology – Our experts will help you select and customize the elements of the Process Value Management (PVM) methodology consistent with current best practices in the discipline.

- Building Your Capability – We will help you develop your internal capability to perpetuate the application of Continuous Process Improvement throughout your organization. Our coaches will train and coach your internal Process Improvement Facilitators in the use of the methodology.

- Process Improvement Implementation – Experienced practitioners will partner with your staff to lead one or more pilot PVM events. The events will address one of the vital opportunities that will be identified during the macro process assessment. Process Improvement Teams will “improve” key business processes beginning with understanding the current process and concluding with implementation of changes.

-

- Follow-up – Experienced practitioners will work with the team leadership to assure the implementation of the team’s action plan. Although this is considered the “final” phase in any process improvement effort, it is actually the beginning phases.